What is the intelligent stereo warehouse and its advantages

Automated Warehouse

A new concept emerging in logistics warehousing. The use of three-dimensional warehouse equipment can realize high-level warehouse rationalization, access automation, and simple operation; automated three-dimensional warehouse is a form with high current technical level.

Compared to traditional warehouses, three-dimensional warehouses have unparalleled advantages, all based on the difference between hardware and the idea of building a warehouse.

The main body of the automated three-dimensional warehouse: consists of shelves, roadway stacking cranes, inbound (out) library workbench and automatic transport (out) and operation control system. The shelf is a steel structure or a reinforced concrete structure of a building or structure. The shelf is a standard size cargo space. The roadway stacking crane runs through the roadway between the shelves to complete the work of depositing and picking up the goods. The management uses WCS. The system controls.

We all know that the WMS system is a warehouse management system. What is the WCS system?

WCS in logistics

The WCS in logistics is the warehouse control system, the full name is Warehouse Control System.

The development of the warehousing system is inseparable from the two key factors of logistics equipment and logistics software.

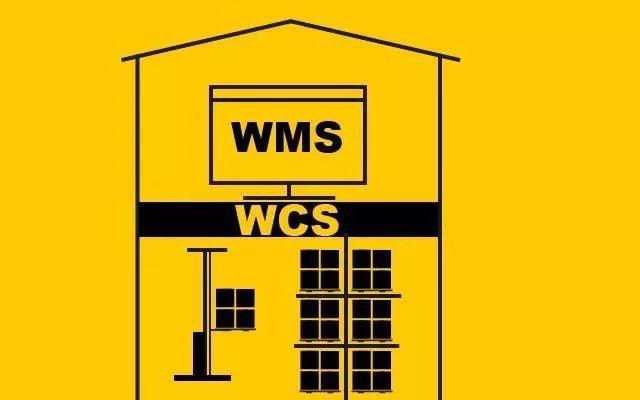

Typically, automated warehouse logistics system software consists of two parts: a warehouse management system (WMS) and a warehouse equipment control system (WCS).

The automatic warehousing system can be roughly divided into three levels. The uppermost layer is WMS, which is responsible for the processing of warehousing business logic; the lowermost layer is the specific logistics equipment, such as roadway stacker and AGV system.

schematic diagram:

The advantages of automated three-dimensional warehouse investment, the advantages of automated three-dimensional warehouse is multi-faceted, for enterprises, it can be reflected from the following aspects.

First, improve space utilization

The basic starting point of the concept of the early three-dimensional warehouse is to improve space utilization and fully conserve limited and valuable land.

In some developed countries in the West, the idea of increasing space utilization has a broader and deeper meaning. Saving land has been linked to more aspects such as energy conservation and environmental protection. Some even treat space utilization as an important indicator of system rationality and advancement.

The basic starting point of the concept of the early three-dimensional warehouse is to improve space utilization and fully conserve limited and valuable land.

The spatial utilization of the stereo library is closely linked to its planning. In general, the automated overhead warehouse has a space utilization ratio of 2-5 times that of a normal flat warehouse, which is quite impressive.

Second, it is easy to form an advanced logistics system to improve the production management level of enterprises

A traditional warehouse is just a place for goods to be stored. The preservation of goods is its only function and is a kind of “static storage”.

The automated three-dimensional warehouse uses advanced automated material handling equipment that not only enables the goods to be automatically accessed in the warehouse as needed, but also can be organically linked to production processes outside the warehouse, and the warehouse is made through computer management systems and automated material handling equipment. An important part of enterprise production logistics.

The purchase of purchased parts and self-made parts into the automated warehouse is one of the production steps. The short-term storage is to automatically output to the next process at the specified time for production, thus forming an automated logistics system. “Storage” is also an obvious technological trend in the development of automated warehouses today.

Reprinted from the network