The top ten picking strategies to improve logistics efficiency, by putting them into logistics applications, can help companies of all sizes to improve their logistics performance. Although the hierarchy is not so strict, the ten strategies are more helpful in understanding in a step-by-step manner. The higher the ladder, the greater the leverage effect of economies of scale and the higher the level of technology.

1.Improve order and warehouse management and control

One of the top ten picking strategies is to use information to strengthen management and provide the necessary information to support accurate business decisions. Most companies, regardless of their size, use certain software for inventory management, material flow control, and device control.

The modern warehouse management system (WMS) and warehouse control system (WCS) are designed to pass the host, all order task information can be displayed in a single user interface, generally using WMS or ERP (Enterprise Resource Planning) system.

With well-designed software for information organization, companies will be able to realize huge supply chain benefits.

2. Real-time logistics solutions for efficiency and error correction

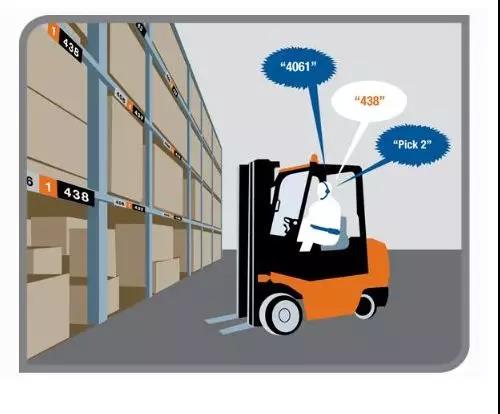

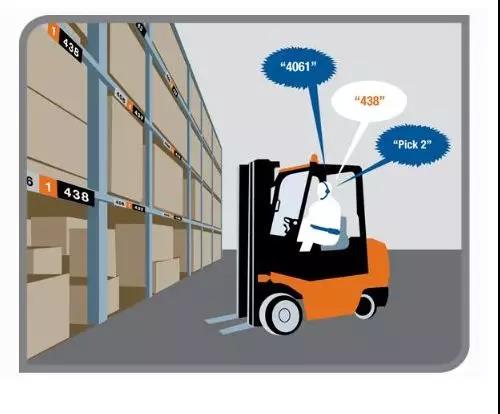

Manual work efficiency in traditional shelf repositories can be enhanced by adding devices that activate data interactions that can send instructions to the product production vehicle in real time, improving throughput, productivity, and accuracy.

Wireless terminals, voice systems and mobile data terminals constitute a paperless environment, which is conducive to real-time transmission of information throughout the supply chain. Not only does this type of equipment increase job efficiency, accuracy and productivity, but it also improves supply chain visibility and traceability, and enables companies of all sizes to find a highly flexible business that can handle change. mode.

3. Compress the picking surface and speed up the walking speed

The results of several studies have proven that one of the most wasted time in order fulfillment is walking. Pickers often need to constantly walk between different positions. In a small, hand-crafted distribution center, there are two ways to easily solve the problem of too much walking, which greatly increases productivity.

Use pallet trucks, forklifts, laser-guided vehicles and other equipment to speed up the picker's walking speed, and cooperate with the intelligent storage system to extend the picking time of the picker and shorten the walking time, thus increasing productivity.

The second method is to compress the picking surface, which can be done with a tray or carton fluent shelf. By storing the goods in the slide behind the picking surface, the purpose of compressing the picking surface is achieved, and the picking surface distance can be reduced by as much as 80%, so that the time spent in the walking process can be greatly shortened during the order picking operation.

4. Adopt intelligent location management conveyor system

Increase the efficiency by making orders actively pick and choose.

By using intelligent material flow control and picking location control conveyor systems, order items flow between different work areas, and pickers do not need to move their positions.

The picking location management solution is especially useful for large and medium-sized companies that order picking and ordering and who want to introduce basic automation technology.

5. Achieve multi-order simultaneous picking to improve picking efficiency

Combine order items from multiple customers into one batch. If the picker can perform batch picking of the goods at each picking position, the work efficiency and system throughput can be greatly improved. FCL applications include moving picking to conveyor belts, which can be used to deliver batch picked items and automatically sorted using intelligent conveyor sorting systems for different order requirements.

In the zero-removal application, the centralized picking technology enables single-station multi-order picking. The picker generally uses the wireless or voice picking vehicle and the electronic label picking system to select the picking and dismantling order for the picker.

6. Using intelligent software to improve efficiency

There are a lot of companies that don’t realize that the pallet selection of some pallets can be completely eliminated. Use smart order fulfillment software to identify opportunities for no picking. By analyzing and cross-matching customer needs, one picking job can be completed while another customer picks up.

The purpose of this concept can be achieved by manual sorting or by machine picking. This technology can be used for both mixed tank sorting and whole-layer picking operations, and the picking efficiency of both can be increased to more than 1400 boxes per hour.

7. Use cache and sorting techniques to avoid walking

This latest and most unique concept of distribution logistics is to completely avoid walking. The pick-and-place picking technology has been used for many years, but what really makes it practical is the power of the computer and the new caching and sorting system. Modern access engine and sequencing technology have brought about a revolution. The High Density and Efficient Automated Warehouse (ASRS) now processes large quantities of goods on demand, with optional bins or pallets to deliver items to picking points or stacking points.

In the high-flow zero-removal and full-box picking operations, new technologies can be used to pre-select, cache, sort, etc. the order goods, and send them to the picking station for picking as needed and on time. This is a new cost-effective delivery solution.

8. Adopting the goods-to-person demolition and zero picking solution

The picker stays in place in an ergonomically designed picking station, eliminating the need for walking, which greatly increases efficiency and meets workplace safety requirements. In the goods-to-person system, the order raw materials that need to be fulfilled are completely moved to the picking staff position as needed. According to the order processing requirements, the picking station and the stacking station can be designed for discrete picking or batch picking.

In addition, a variety of scanning technologies, electronic label picking or voice technology can be used to further improve the efficiency of the picking station.

9. Speed up palletizing speed with cargo-to-person full-box coden solution

FCL picking is very similar to demolition and picking. It also uses an intelligent ergonomic design station that can be used for mixing box codes. Since the pre-selected and sorted mixing bins can be palletized in sequence at the pallet station, the pallet operator can simply slide the carton into place, making the selection easier, faster and safer.

Each station is usually built on a shelf platform and uses integrated transport to continuously deliver the entire container to the station. After each layer of the pallet is completed, the pallet will automatically descend for the upper layer assembly, which will greatly reduce the amount of manual work and improve the safety, speed and quality of the order pallet.

When the tray is lowered, the packaging film can be used to wrap the packaging method to keep the tray stable.

10. Adopt a fully automated picking and palletizing solution

Labor has been used at all levels before, and the idea is to increase the efficiency of manual work by avoiding no added value labor. However, in some cases, if the goods are extremely heavy or the flow rate is extremely high, a fully automated solution can be used.

Advanced results in integrated software, product storage, caching, sequencing and identification, combined with the use of high-speed multi-joint robots and multi-function fixtures, greatly facilitate the development of automated picking and palletizing systems, enabling them to handle a variety of Specifications, including different sizes of boxes, trays, open or closed cartons, bags and sacks.

Each of these systems is extremely accurate, fast, reliable, and can be palletized, denser, and more stable. At the same time, it performs well in terms of palletizing speed, accuracy and ease of use, and can even handle a variety of mixing box specifications. For the zero-removal picking, the A-shaped sorter can be used for automatic sorting, but manual replenishment is still required.

Reprinted from the network