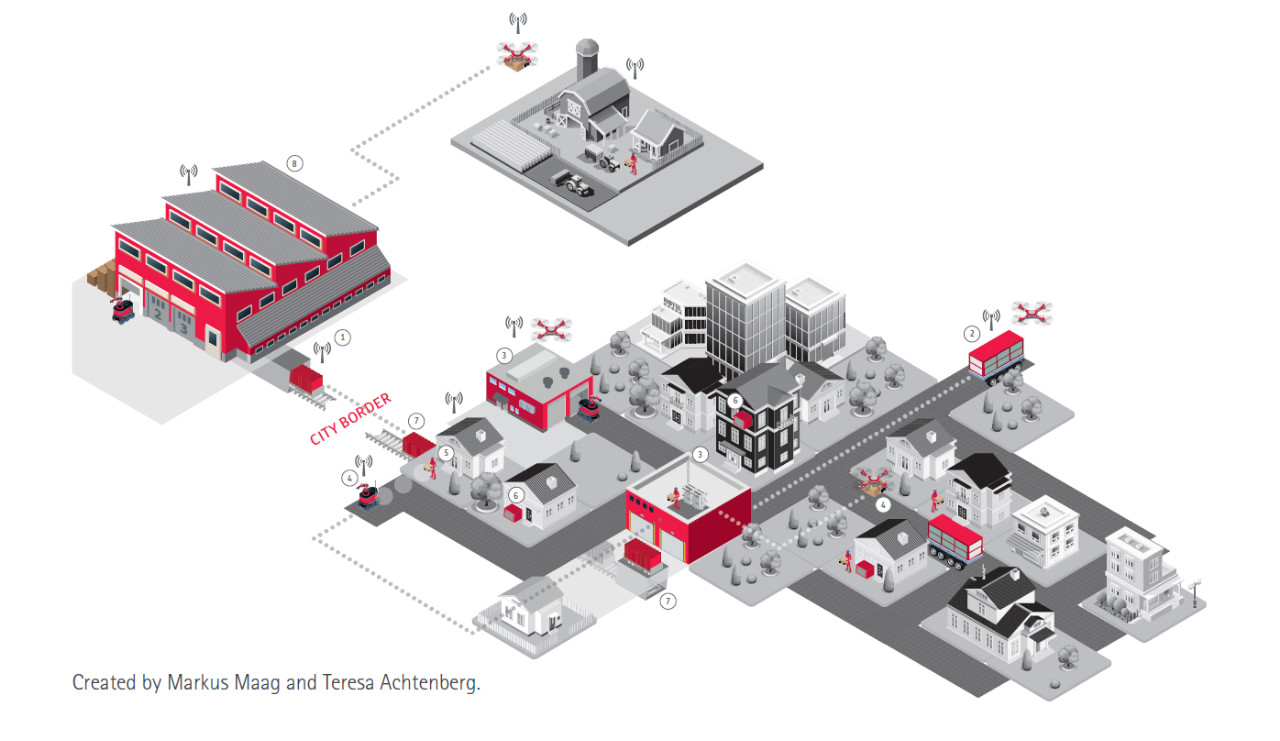

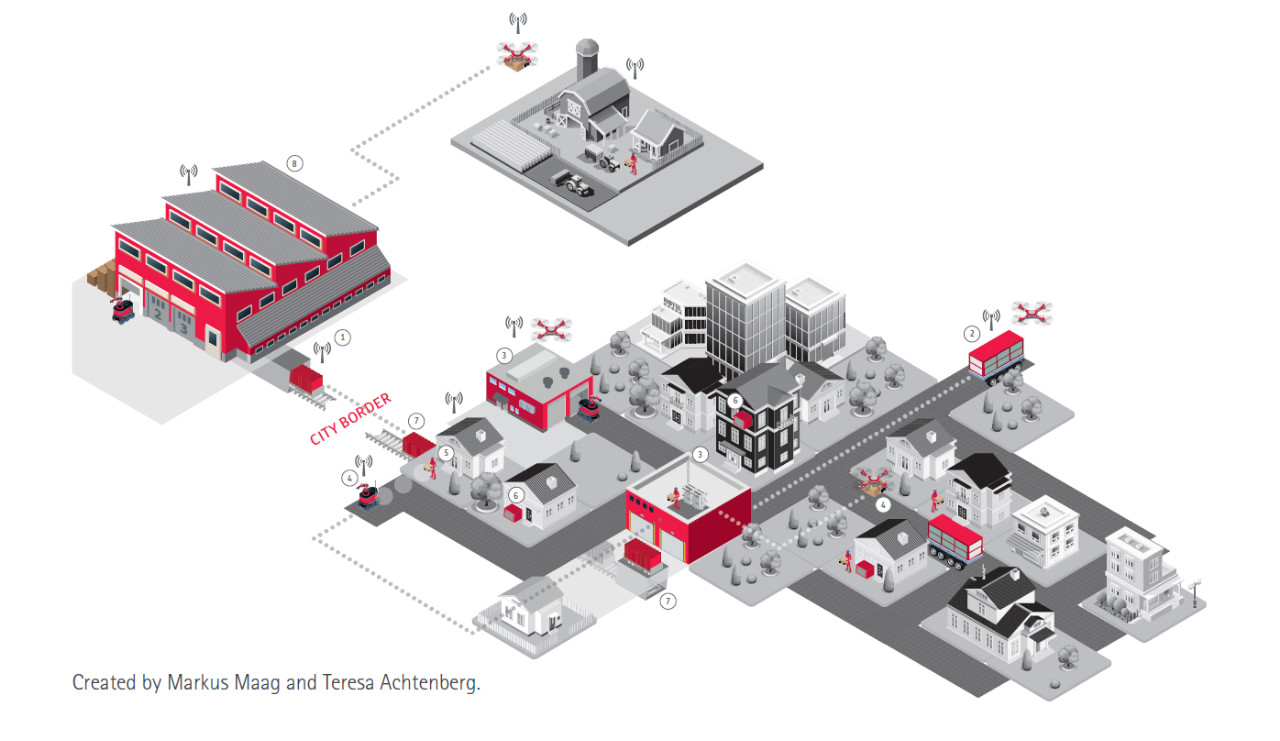

Social trends are driving the shift to many urban distribution centers, bringing key logistics capabilities closer to consumers. A city's distribution center may be a shared service facility that optimizes all logistics processes in its service area or community, including the following core functions:

1) Inventory and order picking

Similar to many warehouses today, urban DCs need to hold some inventory. However, due to limited urban space, product range may continue to expand, so inventory will be limited. In principle, small items and products that are regularly sold will hold inventory. By 3D printing and using big data to predict behavior and distribute items to the city DC before ordering, inventory levels will be kept to a minimum. You also need to use the automated picking system described later in this article for the order picking process. Since City DC will support multiple sellers in a shared service model, this creates the opportunity to consolidate items from different sellers into one shipping carton to reduce shipping costs and enhance the customer experience.

2) 3D printing

Products that are not in stock may be 3D printed. This reduces inventory requirements and allows for the creation of personalized products. The City DC is the ideal location for several large, sophisticated and fast 3D printers. Using the picking scheme described above, it is also possible to combine print materials picked from stock into one package.

3) Parcel integration

Future city DCs will consolidate pre-selected packages from multiple sellers or parcel companies and integrate them into the last mile of transportation to consumers. Functionally, this is no different from many of the parcel sorting centers that exist today. The difference is that logistics and distribution will be combined. In today's networks, companies such as DHL, UPS and FedEx conduct their own sorting and last mile shipping for their customers. The future city DC will integrate the processes of all companies.

4) Key technical support

In addition to supporting these core tasks, urban distribution centers need to adopt some advanced technologies to meet the distribution needs of 2030.

For picking, intelligent robots with advanced grippers can not only select individual products, but also integrate orders from multiple manufacturers in the warehouse and orders from multiple sellers (including 3D printed products) into one shipping carton. Robotic cargo-to-person or fully automated picking solutions, such as SwissLog's AutoPiQ, will support the high-speed picking required by urban DCs.

5) Big data and intelligence

Big data and smart learning will predict which products consumers will order to minimize inventory; however, forecasts are not always correct, which will create additional product movements. Technological advances, such as self-driving trucks and robotic handling systems, will minimize the cost of these moves.

For products that cannot be printed and are unpredictable, new fast long-distance transportation methods can support the delivery of products that are not stored locally. Emerging transportation solutions, such as Hyperloop, can connect large central warehouses with city DCs in major cities. In addition, larger long-haul cargo aircraft can provide flexible, infrastructure-independent long-distance transportation. In addition, automated storage and retrieval systems can be deployed to maximize the number of products that can be stored in the available space.

6) Online market

More DC space is needed to manage the relationship between supply and demand, and it also enables sellers to balance the relationship between their cost and the need for fast delivery. This will reduce the number of distribution centers in a given city and maximize space utilization.

7) Last mile delivery option

There will be many different solutions for the last mile delivery, and the last mile delivery and city DC will need to interact with multiple delivery options.

A significant portion of the package will still be delivered in multiple delivery vehicles. Most likely, this will be an electric and possibly unmanned, similar delivery version of the car. Load large packages efficiently in the shortest possible time. It is likely that some sort of sorting is also needed to be stacked in the order of delivery.

To this end, we can imagine a standardized loading module in which packages can be carried out before the arrival of the vehicle and loaded into the vehicle "once". Inside the vehicle, there may be an automatic form of processing that presents the individual package to the driver. The Daimler Vision van is an early example of this concept. City DC also needs to support customer pickup and mobile pick-up point networks.

In order to support pickup, DC needs a similar "package station" to process overnight packages, which are located in an automated warehouse for storage. It will be a self-loading single locker that consumers can open from the back of the cabinet and take their merchandise.

The mobile pick-up point will quickly fill multiple parcels in the community warehouse and then move closer to the consumer (for example, a shopping mall parking lot) where consumers will pick up the parcel.

Some packages may require a more personalized method of transportation. A wrapped drone or a small autonomous vehicle like an interstellar spacecraft can do this. These methods will require different loading processes as each vehicle is only responsible for the loading of one target location. The warehouse will require a series of small “docks” to park these vehicles and have a way to automatically load them into drones or vehicles.

Another possibility is that consumers will send their autopilot vehicles to collect their parcels. To this end, the DC can use a mobile robot to place the goods in the trunk of the car. It's not hard to imagine that the next generation of KUKA's mobile robots (KMR) will do the same.

Reprinted from the network